GEO-Instruments teamed up with Balfour Beatty on a monitoring scheme for operations taking place at Avonmouth Docks as part of the Hinkley Point C project.

Tier 1 Contractor Balfour Beatty has built six concrete structures; four 5000 tonne intake heads and two outfall heads at Avonmouth that will be connected to five miles of underwater tunnels to supply cooling-water to the new power station.

In order to transport the structures offshore, along the Bristol Channel to their final position on the seabed, they first had to be loaded onto barges from the docks at Avonmouth, then need to be lowered into place via a complex and precise lifting operation.

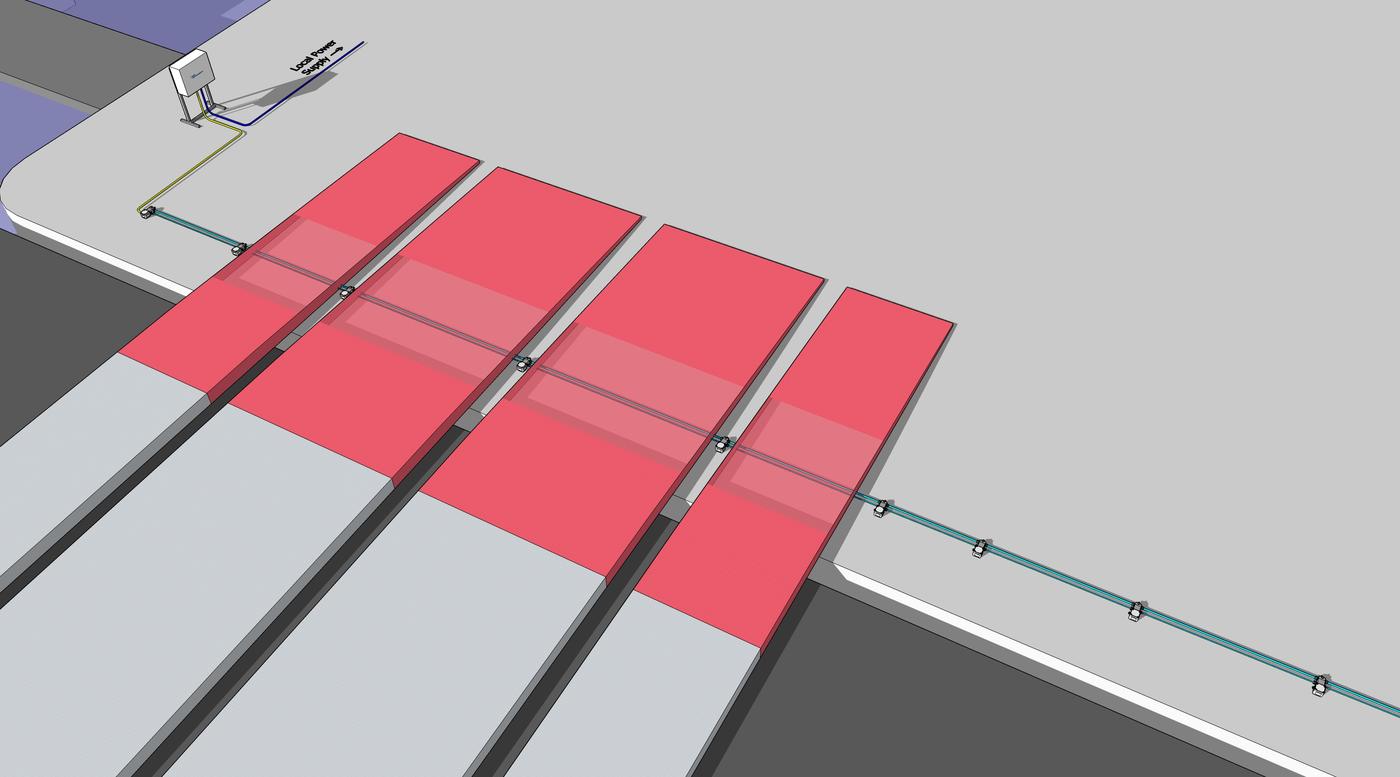

The loading out process from the dock to the barges was a slow and careful operation. The intake heads were gradually transferred from the dock edge via ramps onto the barges. A Hydrostatic Levelling Cell (HLC) system was installed to observe the effect the operation had on the dock edge. Acting principally as a means of Design Verification Monitoring, the HLCs monitored for slight changes in vertical movement of the dock.

GEO-Instruments installed a total of 10 HLCs, with one positioned away from the works area to function as a stable reference. HLCs detect settlement or heave by measuring changes in pressure in a continuous fluid circuit and comparing those to the Reference cell. HLC systems are capable of sub-millimetre accuracy at high frequencies with data automatically collected 24 hours-a-day.

Reggie Harrison, Monitoring Engineer for GEO-Instruments, said, “It has been great to work together with Balfour Beatty on a complex project like this and I am really pleased with the performance of the monitoring scheme. HLCs were the right solution for cost-efficient, real-time data.”

Jim Rolland, Survey Manager for Balfour Beatty, said, “GEO-Instruments set up an HLC monitoring array and live web portal at our Avonmouth site, backed up with great support. This allowed us and our clients to have confidence that no significant movement was occurring along the dock edge during the load out operations. By using the HLCs we were able to remove time consuming monitoring operations and personnel from the works, which proved to be a win all round.”

The heavy-duty nature of the works meant significant risk of damage to the system, therefore measures had to be taken to protect the cells and tubing during the loading out works. Metal coverings and sandbags were used across most of the circuit and sensor positions were chosen carefully.

Effective collaboration with Balfour Beatty allowed the installation and monitoring of the operations to run as smoothly as possible and led to successful delivery of the project.

The process of lifting the Intake and Outfall heads into position off the Somerset coast was successfully completed in September. All the heads are now installed in the Bristol channel ready for next year’s shaft and tunnel connection works to begin.